Tsis Siv Neeg Lub Teeb Hlau Keel Roll Tshuab, UC Channel Roll Forming Tshuab

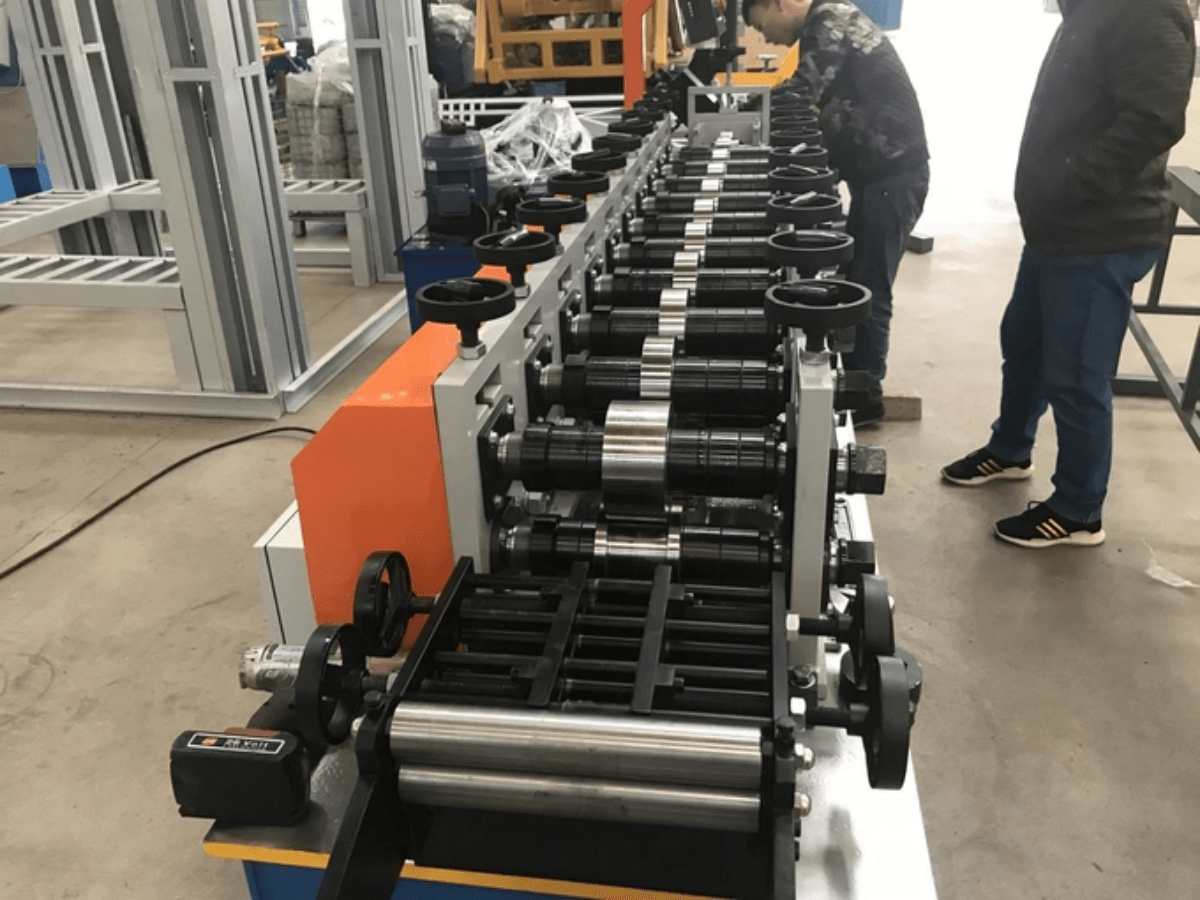

Tshuab duab

Taw qhia

Lub Teeb Steel Keel Roll Forming Tshuab yog siv los tsim ntau yam sib txawv ntawm cov hlau ceilings.Thiab nws tuaj yeem tsim cov ceilings tsis tu ncua.Muab piv nrog cov tshuab dabtsi yog khoov, Lub Teeb Steel Keel Roll Forming Tshuab yog qhov zoo dua, txuag nqi phau ntawv.

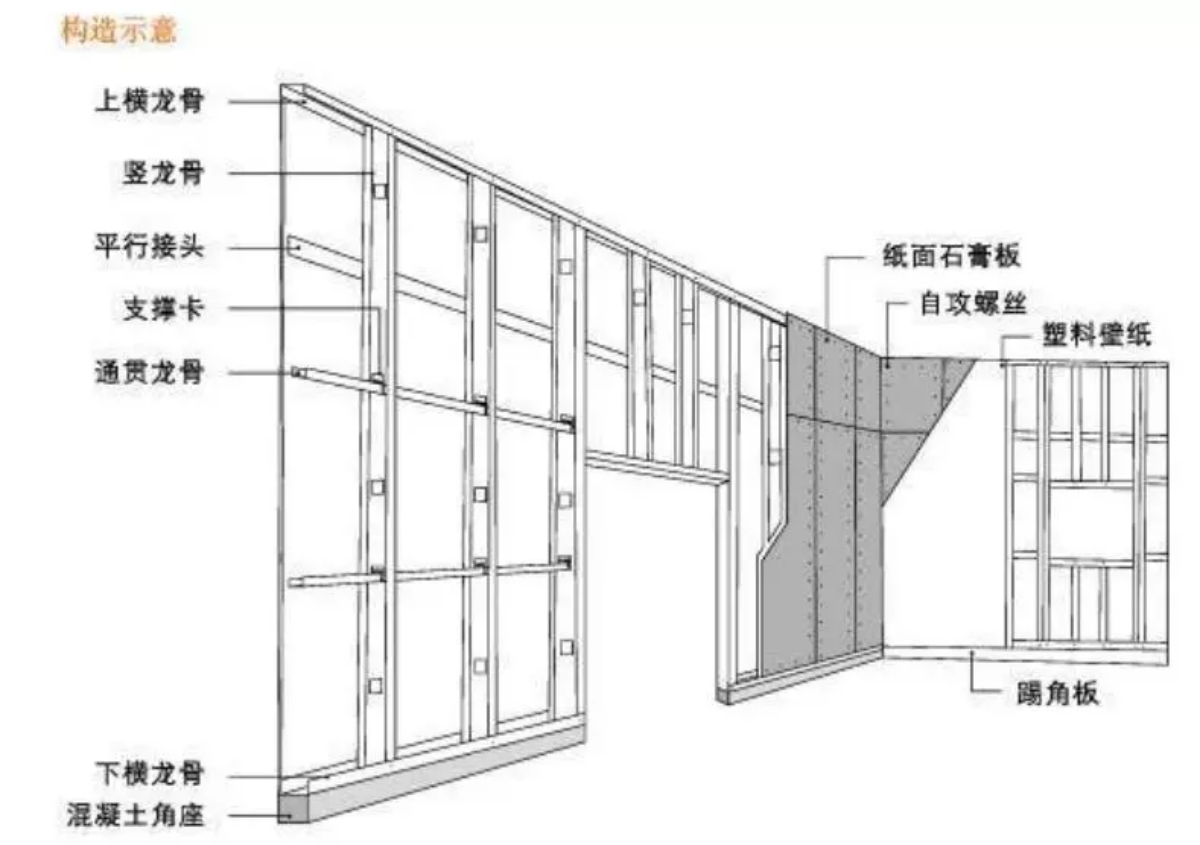

Lub qab nthab zoo feem ntau suav nrog C zoo, U zoo, lub kaus mom zoo, lub kaum sab xis thiab lwm yam. Cov khoom no tau siv dav hauv ntau lub tsev, xws li cov chaw tsim khoom, cov tsev neeg pej xeem, thiab phab ntsa rau cov khoom txuas nrog.Lawv muaj qhov zoo ntawm cov tsos zoo nkauj, siv tau ntev thiab lwm yam.

Cov ntsiab lus technical

| Technical Parameters rau Lub Teeb Steel Keel Roll Forming Tshuab | |||

| Main yob txoj kev tshuab | Raw khoom dav | mm | 150-350 Nws |

| Ua hauj lwm ceev | m/min | 25-45 : kuv | |

| cov chaw nres tsheb | chaw nres tsheb | 11-13 | |

|

Lub cev muaj zog | Main lub cev muaj zog | kw | 7.5 |

| Hydraulic Chaw nres tsheb fais fab | kw | 4 | |

| Otehrs | Hluav taws xob tswj System | PLC hom | nto moo hom |

| Khoom Thickness | mm | 0.3-1.0 hli | |

| Txiav raug | mm | ± 2 | |

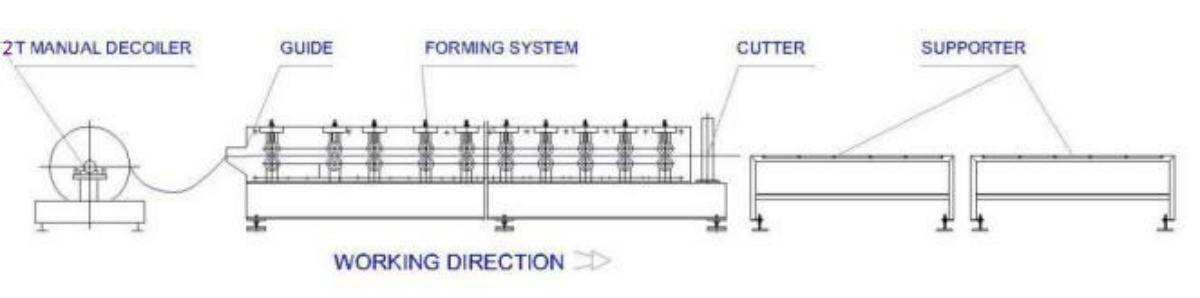

Cov Cheebtsam

| Lub npe | Ntau | Chav tsev |

| Mannaul Uncoiler | 1 | Teeb |

| Khoom noj khoom haus | 1 | Teeb |

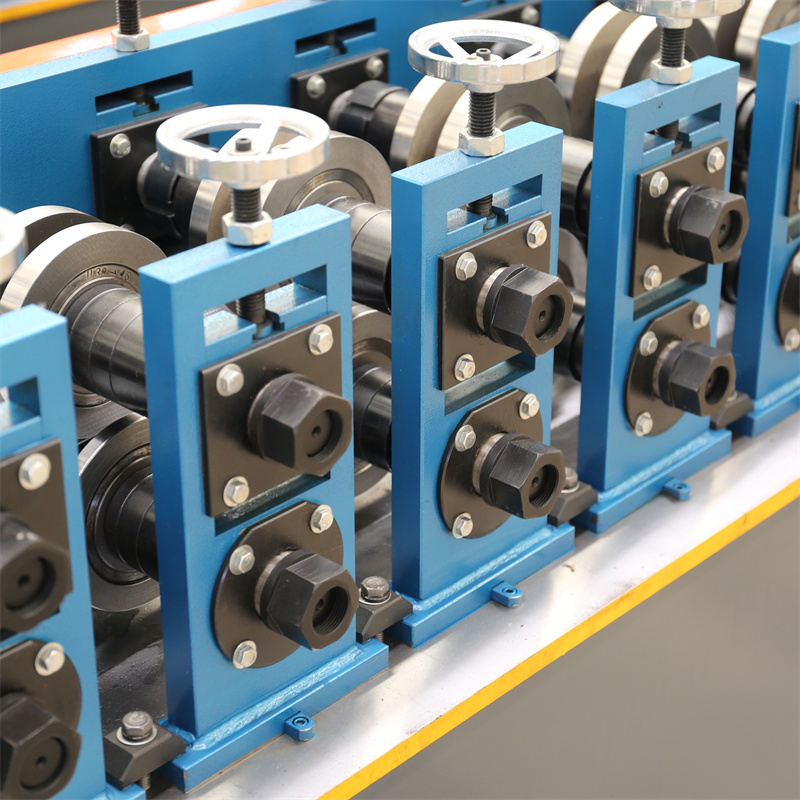

| Lub Main Roll Forming System | 1 | Teeb |

| Hydraulic Device | 1 | Teeb |

| Chaw nres tsheb Hydraulic | 1 | Teeb |

| PLC System | 1 | Teeb |

| Txais Lub Rooj | 2 | Teeb |

Tsim Nyog

Uncoiling daim ntawv --- Roll forming --- Rectifying qhov ncaj --- Ntsuas qhov ntev --- Txiav lub vaj huam sib luag --- txais lub rooj

Qhov zoo

· Lub teb chaws Yelemees COPRA software tsim

· 5 engineers nrog ntau tshaj 20 xyoo kev

· 30 tus kws tshaj lij kws tshaj lij

· 20 teeb tsa cov kab ntau lawm CNC ntawm qhov chaw

· Pab neeg mob siab rau

· Kev teeb tsa engineers tuaj yeem ncav cuag koj lub Hoobkas hauv 6 hnub

· 1.5 xyoo txij nkawm thiab tag nrho lub neej kev txhawb nqa

Daim ntawv thov

Qhov kom zoo dua ntawm cov khoom kawg CU Keel muaj xws li zoo nkauj, classical tsos thiab kev hlub saj.Nws yog dav siv nyob rau hauv lub zos, tsev so, exhibition, so lub zos, tsev neeg kev tsim kho thiab sab nraum zoov decorating.

Khoom duab

Peb Cov Kev Pabcuam

1. Cov khoom tswj tau zoo thiab lub sijhawm xa khoom yog tswj hwm nruj;

2. Lub Hoobkas ncaj qha muab cov nqi sib tw;

3. Tag nrho cov lus nug yuav teb rau hauv 12 teev;

4. OEM & ODM kev pabcuam muaj;

5. Muab cov kev pab cuam tom qab muag thawj zaug rau cov neeg siv khoom.

Kev teeb tsa thiab kev cob qhia

Yog tias cov neeg yuav khoom tuaj xyuas peb lub Hoobkas thiab xyuas lub tshuab, peb yuav qhia koj yuav ua li cas rau nruab thiab siv lub tshuab thiab tseem cob qhia koj cov neeg ua haujlwm / kws kho mob ntsej muag.

Yog tsis tau mus xyuas, peb yuav xa koj cov neeg siv phau ntawv thiab yees duab los qhia koj rau nruab thiab khiav lag luam.

Yog tias tus neeg yuav khoom xav tau peb cov kws tshaj lij mus rau koj lub Hoobkas hauv zos, peb cov engineers tuaj yeem mus rau koj qhov chaw los ua lub installation