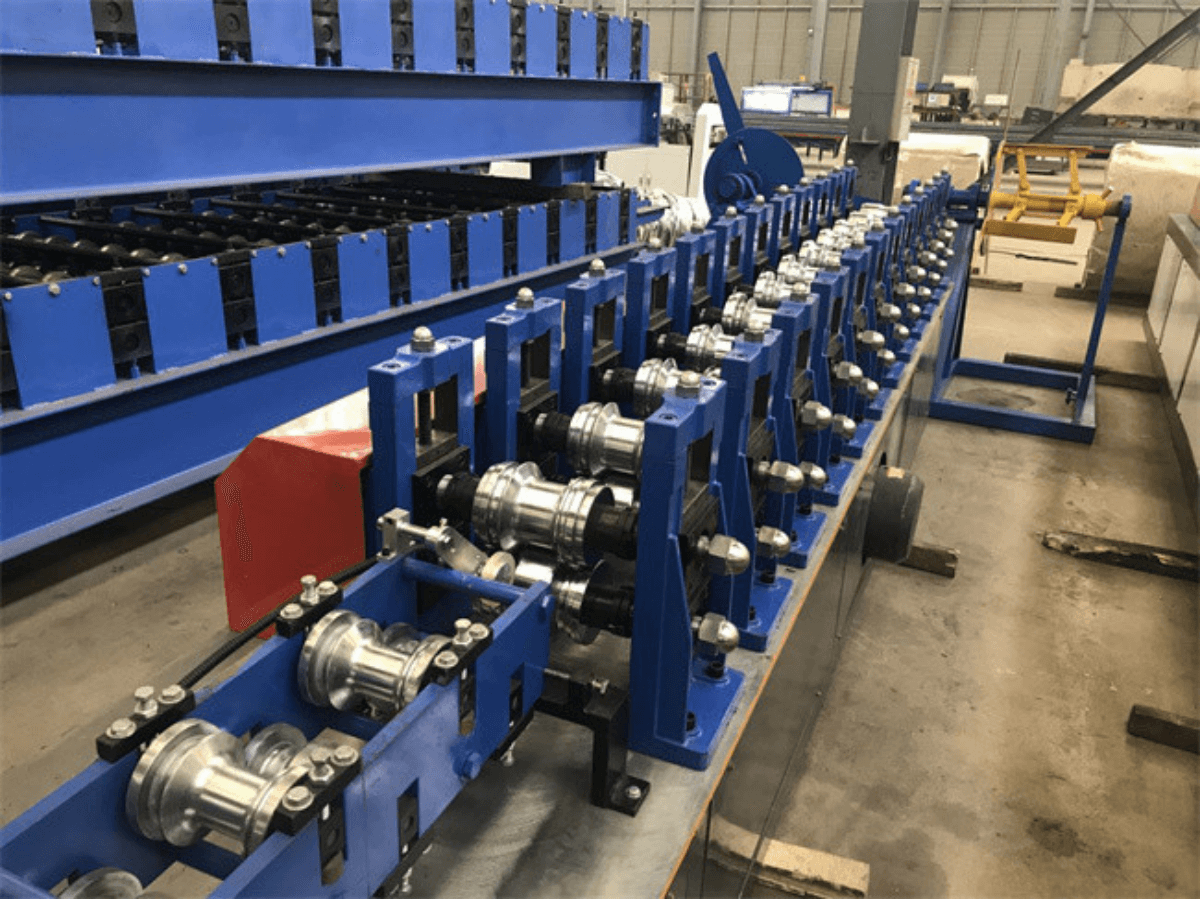

Tuam Tshoj Hlau Txhuas Cov Menyuam Shutter Qhov Rooj Yob Txoj Kev Ua Tshuab Rau Dov Qhov Rooj

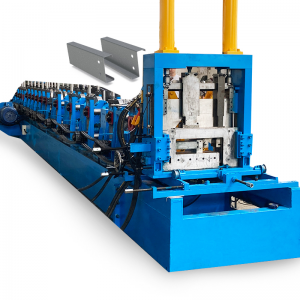

Tshuab duab

Kev piav qhia

Roller shutter qhov rooj ua tshuab muaj ntau yam:

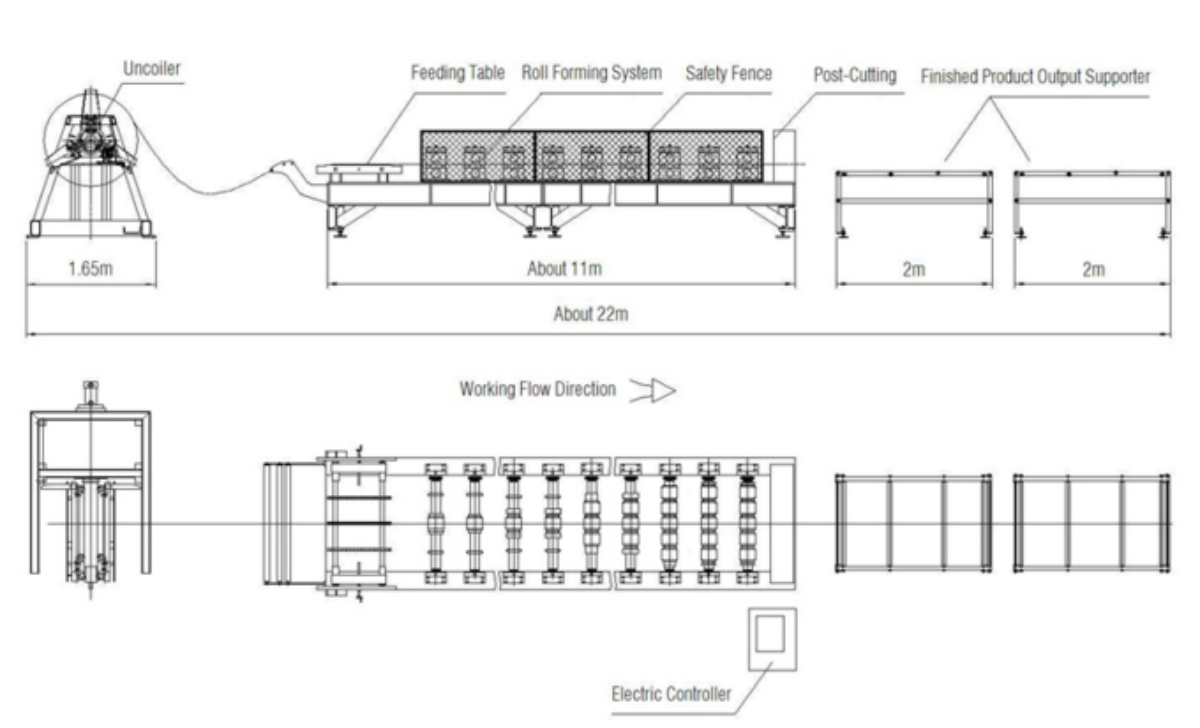

1. Decoiler lub kauj.

2. Feeder rau lub tshuab xuas nrig ntaus tshuab (nws tuaj yeem ua rau lub qhov rooj kaw qhov swb npog nrog qhov).

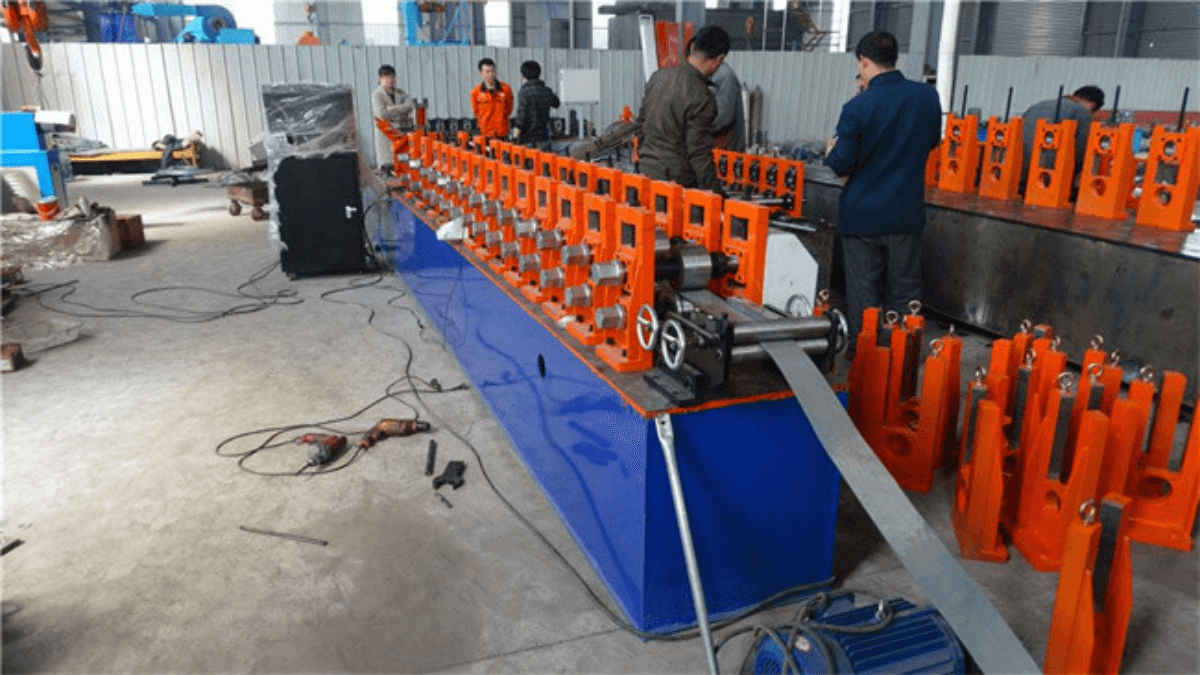

3. Roll forming ib feem, rau peb mahcine, qhov sib sau ceev yuav yog 0-30m / min, nws yog asjustable.Feem ntau peb yuav ua rau Shutter qhov rooj yob txoj kev tshuab nrog iav tsav, nws yuav muab machie lub zog muaj zog txav.

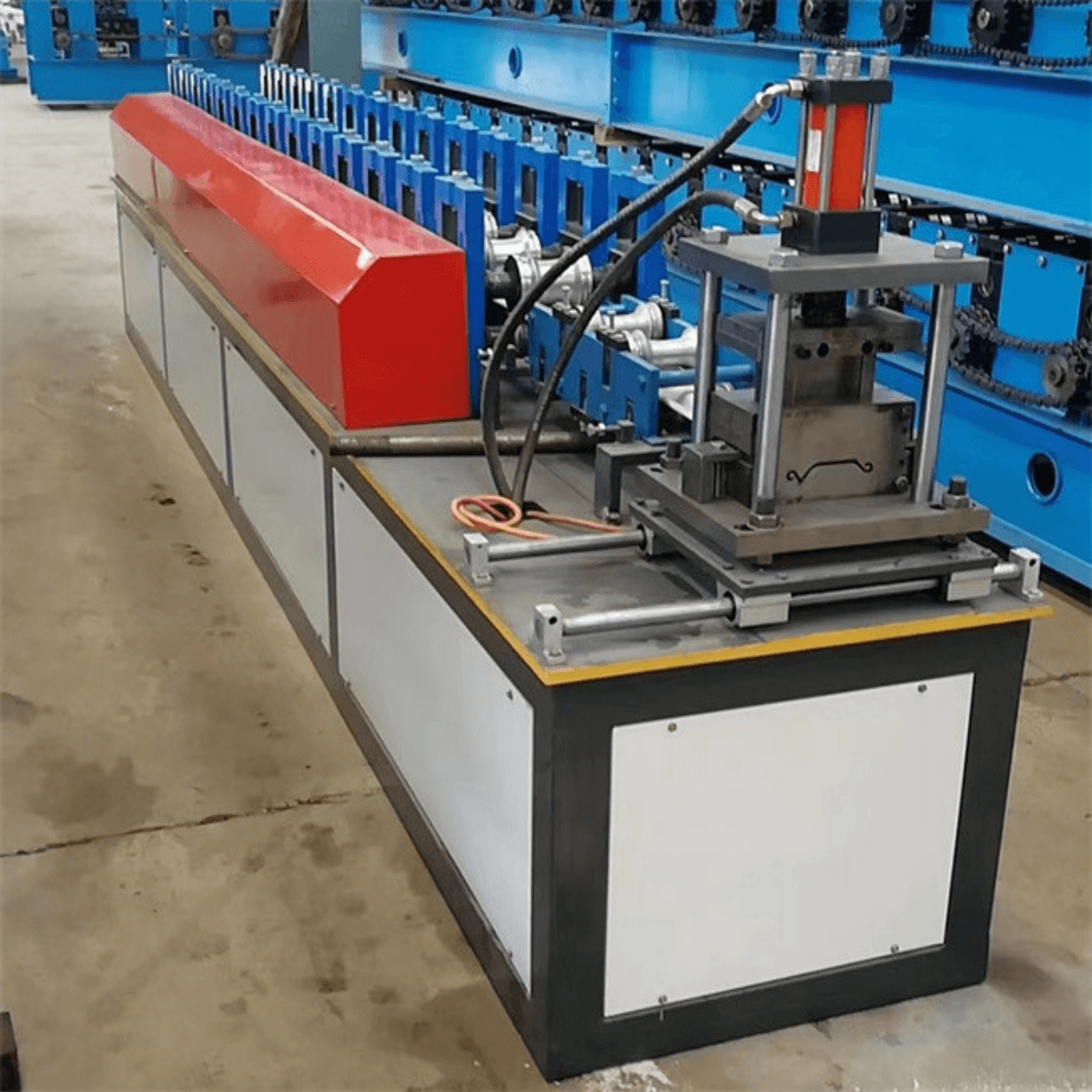

4. Punching lub xauv qhov.Qhov no yuav ua ke nrog txiav hniav.Thaum nws txiav, lub tshuab yuav xuas nrig ntaus lub qhov ua ke.

5. Txiav ntu.Peb muaj ob hom cutter rau koj xaiv, ib qho yog ya saw, lwm yam yog hydraulic cutter.

Peb lub Hoobkas yog tsim cov tshuab kaw qhov rooj zoo, thiab tsis tu ncua xa tawm mus rau Australia, USA, Thaib, Canada, Indonesia, Philippines, Malaysia, Angola, thiab lwm yam, Colombia, Rwanda, South Africa.

Cov ntsiab lus technical

| Tshuab Specifications | |

| Qhov hnyav | Txog 3.5 tons |

| Loj | Luas = 5.6 m x 1.2 m x 1.3 m (ntev x dav x qhov siab) |

| Xim | Lub ntsiab xim: xiav los yog raws li koj xav tau |

| Xim ceeb toom: daj | |

| Haum Raw Khoom | |

| Khoom siv | Galvanized Steel Coils |

| Thickness | 0.5-0.8mm los yog 0.8-1.5mm |

| Yield zog | 235 Mpa |

| Main Technical Parameters | |

| Qhov ntau ntawm kev sib sau cov chaw nres tsheb | 11-12 |

| Txoj kab uas hla ntawm txoj kev rollers shafts | 60 hli |

| Roll Forming Ceev | 15-20m / min |

| Kev tsim cov khoom siv rollers | No.45 steel, coated nrog chromed kev kho mob |

| Cutter khoom | CR12 pwm steel, nrog quenched kev kho mob |

| Tswj qhov system | PLC thiab Converter |

| Hluav taws xob xav tau | Main lub cev muaj zog: 4kw |

| Hydraulic unit lub cev muaj zog: 3kw | |

| Hluav taws xob voltage | Raws li cov neeg siv khoom xav tau |

Tsim Nyog

Uncoiling daim ntawv --- Infeed guiding --- Roll forming --- Rectifying qhov ncaj --- Ntsuas qhov ntev --- Txiav lub vaj huam sib luag --- vaj huam sib luag rau tus neeg txhawb nqa (kev xaiv: tsis siv neeg stacker)

Peb Lub Hoobkas Zoo

· Lub teb chaws Yelemees COPRA software tsim

· 5 engineers nrog ntau tshaj 20 xyoo kev

· 30 tus kws tshaj lij kws tshaj lij

· 20 teeb tsa cov kab ntau lawm CNC ntawm qhov chaw

· Pab neeg mob siab rau

· Kev teeb tsa engineers tuaj yeem ncav cuag koj lub Hoobkas hauv 6 hnub

· 1.5 xyoo txij nkawm thiab tag nrho lub neej kev txhawb nqa

Daim ntawv thov

Lub tshuab no yog siv dav hauv kev tsim cov qhov rooj kaw.

Khoom duab

FAQ

Q1.Koj cov nqe lus them nqi thiab lub sijhawm xa khoom yog dab tsi?

A1: 30% raws li qhov tso nyiaj los ntawm T / T ua ntej, 70% raws li qhov nyiaj tshuav ntawm T / T tom qab koj kuaj xyuas lub tshuab zoo thiab ua ntej xa khoom.Tau kawg koj cov nqe lus them nqi tau txais.Tom qab peb tau txais cov nyiaj them poob qis, peb yuav npaj ntau lawm.Txog 30-45 hnub rau kev xa khoom.

Q2.Koj puas muaj kev txhawb nqa tom qab muag?

A2: Yog lawm, peb zoo siab los muab cov lus qhia thiab peb kuj muaj cov kws tshaj lij tshaj lij thoob ntiaj teb.

Q3.Koj puas muag cov tshuab txheem xwb?

A3: Tsis yog, feem ntau ntawm peb cov tshuab tau tsim raws li cov neeg siv khoom tshwj xeeb, siv cov khoom lag luam sab saum toj.

Txais tos kom nug.