Lub zog tseem ceeb 22KW CZ Purlin Roll Forming Tshuab Ceev Hloov Siab Durability

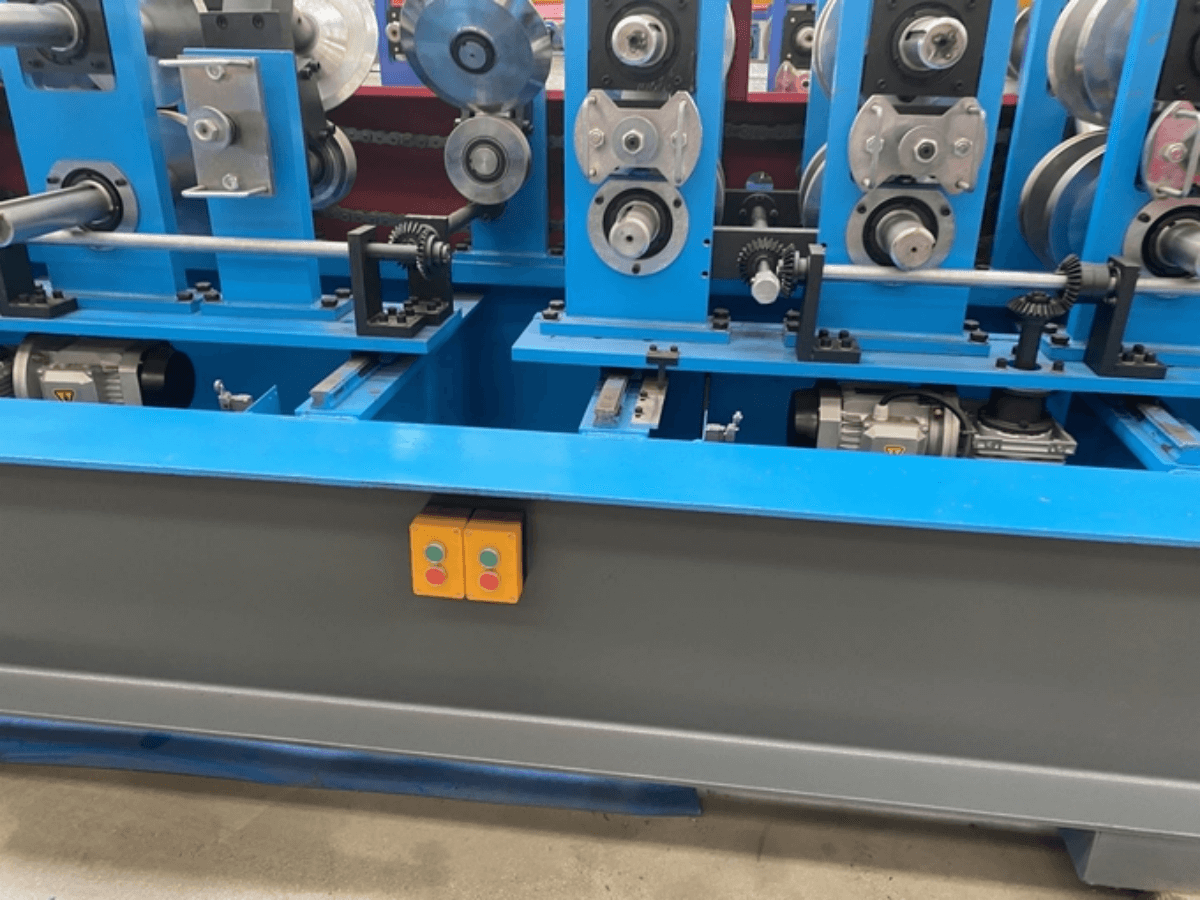

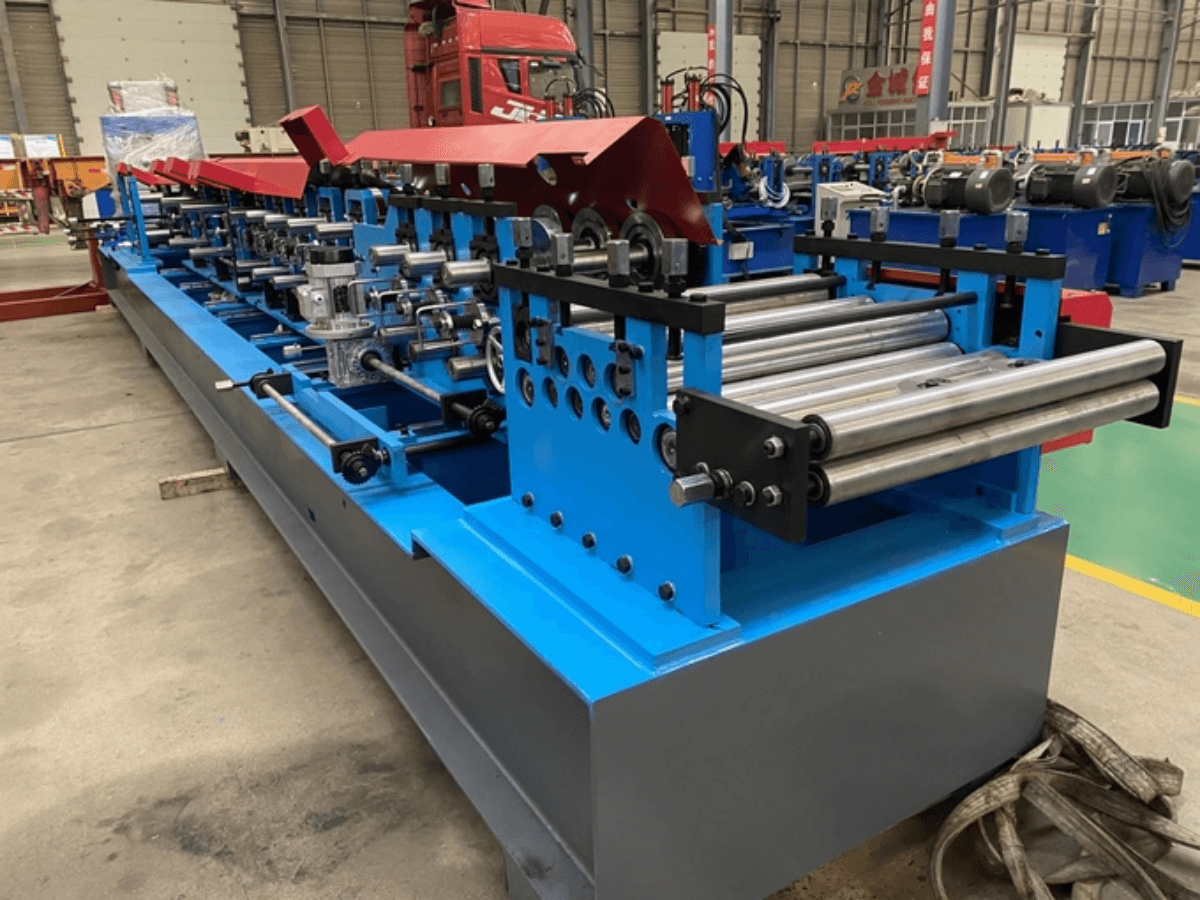

Tshuab duab

Kev piav qhia

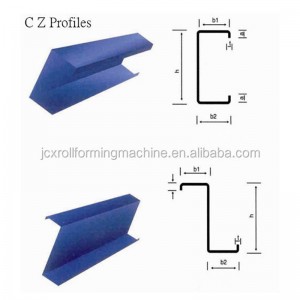

Yuav ob lub yob txoj kev tshuab (C Purlin Roll Forming Machine & Z Purlin Roll Forming Machine) tsis yog qhov kev daws teeb meem zoo tshaj plaws rau cov neeg cog lus lossis cov neeg xa khoom.Raws li qhov tshwm sim, peb cov kws tshaj lij yob txoj kev tsim cov kws tshaj lij tau pom tawm ib hom tshiab yob txoj kev tshuab duab hauv lawv lub siab.

Thaum kawg, peb CZ purlin interchangeable yob txoj kev tshuab tau tsim los tsim ob qho tib si C thiab Z steel purlins nrog txhua qhov ntau thiab tsawg.

Qhov kev hloov pauv nrog rau kev txiav tuag rau C rau Z yuav siv sijhawm ntau tshaj 30 feeb (tsuas yog clutches tawm, 180 ° tig rau qee cov cuab yeej dov thiab clutches ntxig rau hauv) thiab qhov hloov pauv loj xav tau ntau tshaj 5 feeb (tsuas yog nkag mus rau qhov xav tau nyob deb ntawm qhov kov npo ntawm PLC tswj txee).Yog li ntau qhov kev ua tau zoo tau txhim kho los ntawm qhov hloov pauv ceev c / z steel purlin yob txoj kev tshuab

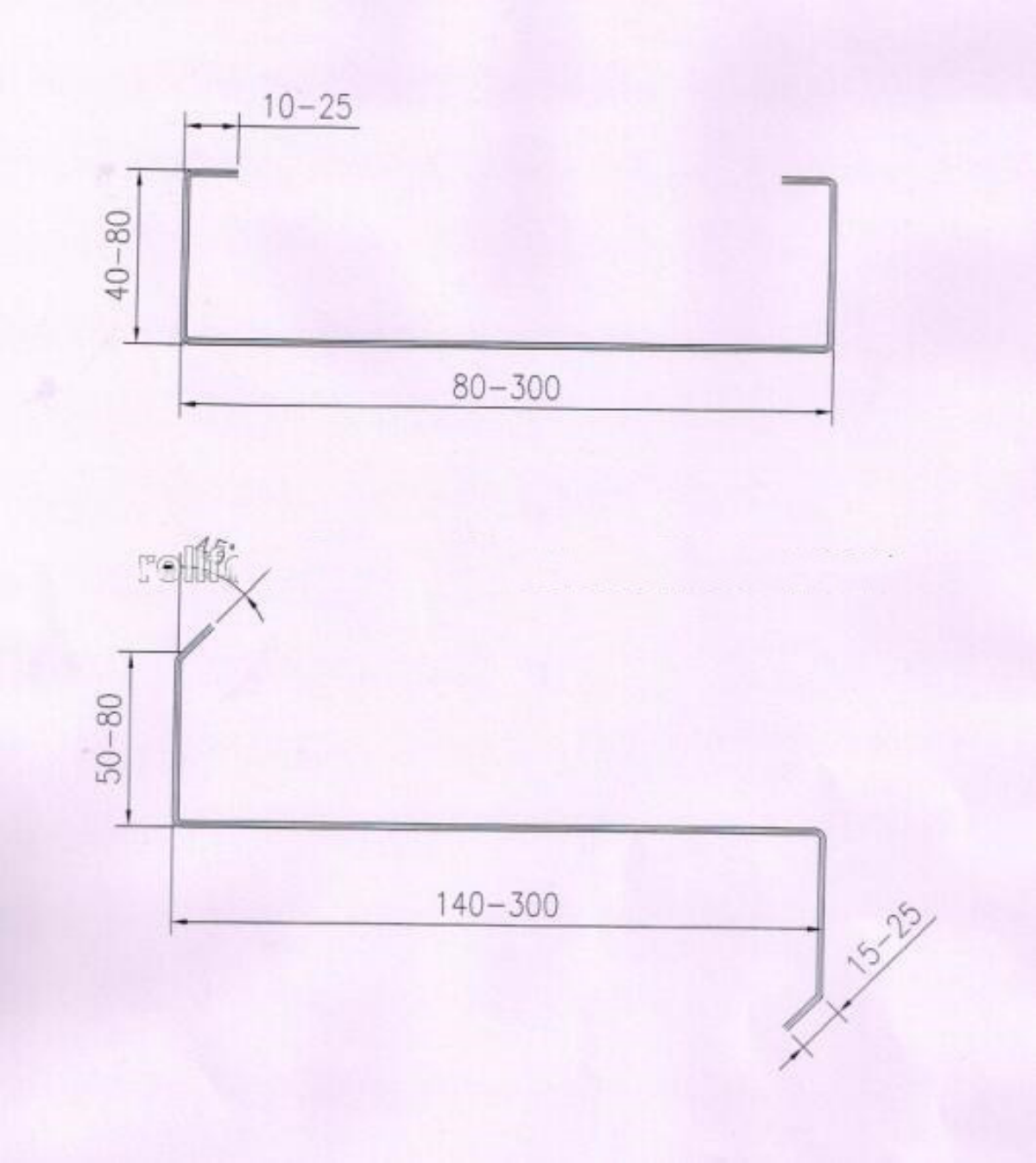

Kev kos duab profile

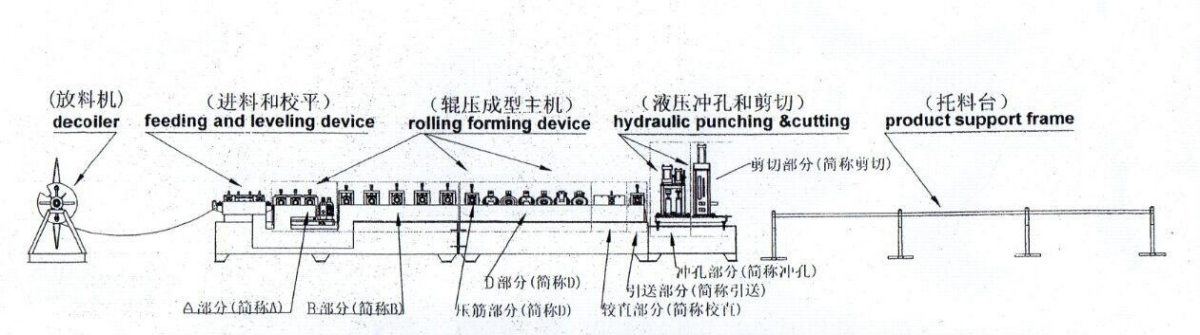

Kev ua haujlwm

Tshuab Specification

| Tshuab Specifications | |

| Qhov hnyav | Txog 9.5 tons |

| Loj | 10.1 * 1.2 * 1.2m (ntev x dav x qhov siab) |

| Xim | Lub ntsiab xim: xiav los yog raws li koj xav tau |

| Xim ceeb toom: daj | |

| Haum Raw Khoom | |

| Khoom siv | Galvanized Steel Coils |

| Thickness | 1.5-3.0 hli |

| Yield zog | 235 Mpa |

| Main Technical Parameters | |

| Qhov ntau ntawm kev sib sau cov chaw nres tsheb | 18 |

| Txoj kab uas hla ntawm txoj kev rollers shafts | 60 hli |

| Roll Forming Ceev | 15-25m / min |

| Kev tsim cov khoom siv rollers | No.45 steel, coated nrog chromed kev kho mob |

| Cutter khoom | Cr12MoV steel, nrog quenched kev kho mob |

| Tswj qhov system | PLC thiab Converter |

| Hluav taws xob xav tau | Lub cev muaj zog lub cev muaj zog: 22kw hydraulic lub cev muaj zog |

| Hluav taws xob voltage | Raws li cov neeg siv khoom xav tau |

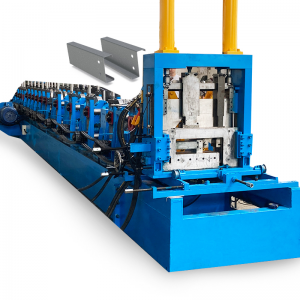

Tshuab duab

Daim ntawv thov

Lub CZ purlin uas tau tsim los ntawm CZ purlin yob txoj kev tshuab tuaj yeem siv rau cov qauv kev ntxhov siab loj ntawm cov kev lag luam loj thiab nruab nrab thiab kev tsim kho pej xeem.Lub ru tsev load bearing thiab phab ntsa vaj huam sib luag txhawb nqa cov nroj tsuag, warehouses, engine tsev, hangars, exhibition halls, cinemas, gymnasiums, ncaj paj sawv, thiab lwm yam.

Peb Cov Kev Pabcuam

A. Txawv Teb Chaws Debugging

Yog tias koj xav tau, peb yuav npaj peb cov kws tshaj lij engineers los pab koj nruab thiab kho cov cav tov kom zoo.Tus neeg yuav khoom yuav tsum them $ 60 toj ib hnub

B. Lub Sijhawm lav

Lub warranty yuav yog kev saib xyuas, tswj nyob rau hauv lub sij hawm lav ntawm 18 lub hlis pib txij thaum xa khoom.Vim tias cov khoom siv tau zoo thaum lub sijhawm lav, peb yuav muab cov khoom tsis pub dawb, uas yog nyob rau hauv cov xwm txheej ntawm kev ua haujlwm raug.(Kev puas tsuaj ntuj tsim los yog yam uas tsis tuaj yeem yuam los ntawm tib neeg raug cais tawm).

C. Kev cob qhia

Thaum lub sij hawm installation thiab kho cov cuab yeej, peb cov engineers yuav tsum muab kev cob qhia rau

tus neeg yuav khoom thov kom ua haujlwm thiab tswj cov khoom siv.Nrog rau kev tsim kho hauv paus, hluav taws xob ua haujlwm, roj hydraulic, kev ua haujlwm nyab xeeb thiab cov khoom tsis zoo, cov khoom siv kuaj thiab lwm yam.

D. Kev Pabcuam Lub Neej

Lub neej kev pabcuam rau txhua tus neeg siv khoom.